In Glass Blowing the Furnace Where the Work is Reheated to Continue Working

Glass Heating Methods

Glass blowing is a highly skilled, long practiced art form of shaping molten glass. Today, glassblowers use many heating methods to keep the glass above a required temperature of 1000° F. Glass can be heated by a series of furnaces or by a gas torch in a process called torchworking, lampworking, or flameworking.

Furnaces

Glass can be inserted into a series of 3 different furnaces to keep it molten and workable. The first furnace contains a crucible to hold the glass materials as they first melt. The second furnace is known as the "glory hole." It contains an opening through which the glass can be re-heated as needed during the shaping process. The third furnace is the annealer which carefully reduces the heat of the molten glass so it does not thermally shock and shatter. Blown glass can spend hours or days in the annealer, depending upon the size, and thickness of the object.

Torchworking

Early torchworking involved heating glass over an oil lamp. Glassblowers today use torches that burn a number of gases such as a propane torch, natural gas, butane, or a mix of methylacetylene and propadiene. Glassblowers use canisters of fuel in addition to a continuous supply of oxygen. Oxygen mixes with their preferred fuel inside the tip of the torch.

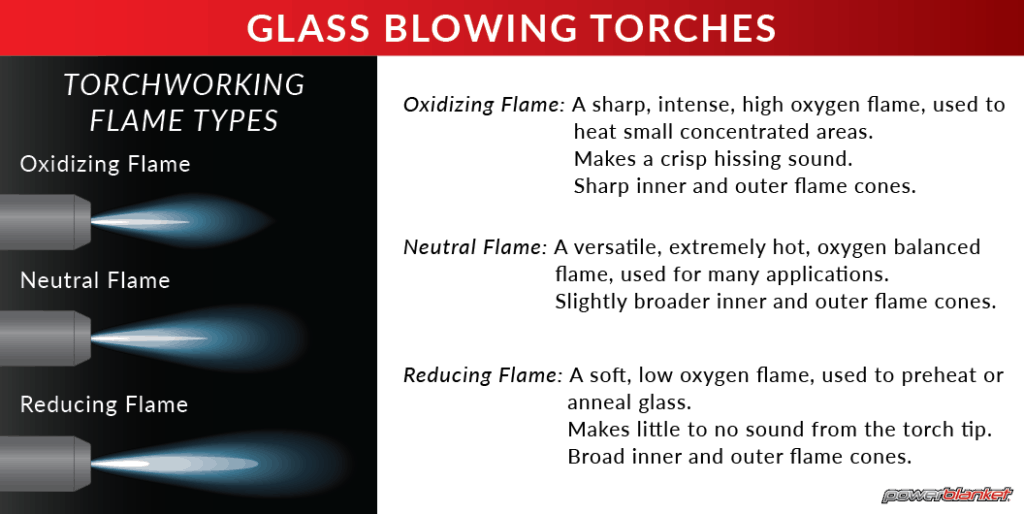

Torch Settings

It is crucial that glassblowers understand and use the chemistry of their torch flame. There are 3 essential torchworking flame types: oxidizing, neutral, and reducing (or carburizing). Glassblowers create these flames by adjusting the blend of fuel to oxygen in their torch tip. Torches do not have 3 different settings to help glassblowers find the correct flame for their needs. Instead, these flame types exist on a wide spectrum. As a result, torchworkers need to become familiar with how they look and sound.

Oxidizing Flame

An oxidizing flame contains higher levels of oxygen than fuel. It makes a crisp hissing sound when it exits the torch tip. The flame shape is usually sharp and intense.

Neutral Flame

The perfect balance of fuel and oxygen makes this the hottest and most useful flame for torchworking.

Reducing Flame

A reducing flame contains more fuel and less oxygen. It then burns up oxygen in the ambient air surrounding the glass which can cause a carburizing effect as it introduced carbon into the molten glass. Reducing flames are cooler and make little or no sound as they exit the torch tip.

Utilizing Different Flames

Discovering the uses for different torch flames requires great skill and practice. Each flame has the ability to affect the colors and overall look of a piece of blown glass. The distance of the flame to the glass also has a great effect on the final piece. Torchworkers need to try out different flames, distances, fuel types, and raw materials to find their preferred glassblowing solutions.

Powerblanket Torchworking Solutions

Glass blowing is a year-round pursuit for many. And when winter rolls around, it poses some obstacles for flame working. No matter what gas you use for your torchworking, you're probably well aware of the effect cold weather has on your gas storage. If you have to store your cylinders or tanks in an outside location (or in a cool warehouse), you run the risk of severe depletion and low pressure come winter, or even cooler fall and spring temperatures for that matter. However, there's no need to fear. You can protect your torch gases with a safe, efficient, and easy-to-use gas cylinder heater from Powerblanket.

Gas Cylinder Heaters

Poor tank pressure means poor flow rates, and you can't have that when you're torchworking. If the gas cools too much, it will also liquefy or separate. Powerblanket has developed gas cylinder heaters that keep your torchworking gases at ideal working temperatures, regardless of how cold it gets.

Powerblanket propane tank heaters, gas delivery systems, and gas cylinder heaters are fully insulated and are certified to UL, CSA and CE safety standards. With particular relevance to torching applications, Powerblanket heating solutions are available with hazardous location certifications for Class I Division 2. This means they can be safely used in C1D2 hazardous locations, such as a workshop where there might be flammable gases in the atmosphere.

Contact us to find the right gas storage solutions for your glass blowing needs at 855.401.0395 or [email protected]

Powerblanket's superior heating solutions reduce costs by optimizing container temperatures and increasing cylinder efficiency.

Source: https://www.powerblanket.com/blog/glass-blowing-heating-solutions-flame-working/

0 Response to "In Glass Blowing the Furnace Where the Work is Reheated to Continue Working"

Publicar un comentario